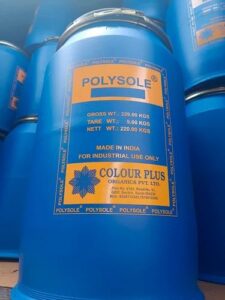

Polysol Textile Chemical Product Description

Polysol is a versatile textile chemical designed to enhance the performance and quality of various textile materials. It is primarily used in the textile industry for processes such as dyeing, finishing, and printing. Polysol is known for its excellent solubility, stability, and compatibility with a wide range of fibers, including cotton, polyester, and blends. This product is formulated to improve the overall feel, appearance, and durability of textiles, making it an essential component in modern textile processing.

Uses of Polysol

- Dyeing: Enhances color uptake and uniformity in dyeing processes.

- Finishing: Improves the softness, drape, and overall hand feel of fabrics.

- Printing: Aids in achieving vibrant and long-lasting prints on textiles.

- Stain Resistance: Provides protective properties against stains and spills.

- Water Repellency: Enhances the water-resistant characteristics of fabrics.

- Antimicrobial Properties: Offers protection against bacteria and fungi, extending the life of textiles.

Technical Data

| Property | Value |

|---|---|

| Appearance | Clear to slightly hazy liquid |

| pH (1% solution) | 6.0 – 8.0 |

| Solubility | Soluble in water |

| Density (g/cm³) | 1.05 – 1.10 |

| Viscosity (cP) | 100 – 300 |

| Flash Point (°C) | > 100 |

| Shelf Life | 12 months (when stored properly) |

| Recommended Dosage | 1 – 5% based on weight of fabric |

Key Benefits

- Versatility: Suitable for a wide range of textile applications.

- Eco-Friendly: Formulated with environmentally safe ingredients.

- Cost-Effective: Reduces the need for multiple chemicals, streamlining the production process.

- Enhanced Performance: Improves the durability and aesthetic appeal of textiles.

Polysol is an essential product for textile manufacturers looking to improve the quality and performance of their fabrics while maintaining efficiency in their production processes.